This was a tour we booked at the last minute and was our last full day in Bologna and our chance to get out of the city. But first, we made a stop at one of the oldest pastry & coffee shops in Bologna. I could find it again………….but never got the name nor a photo of the outside. We ordered our beverage of choice and a pastry while Ricardo prepped us for the day’s activities.

First stop on today’s tour – cheese – and we headed to Modera.

We got picked up fairly early (7 am) to ensure we saw (most) of the cheese-making process for Parmasean. We missed two steps, the curdling of the milk and subsequent separation. Use your imagination from the photos below. Curdling occurs naturally if cows’ milk is left open in a warm environment to air.

Separation of the curdling gives you this delicious Ricotta. I’ll state this right now………this is not a post about cheese-making, listing all of the sciences and steps involved. If you need that – google it.

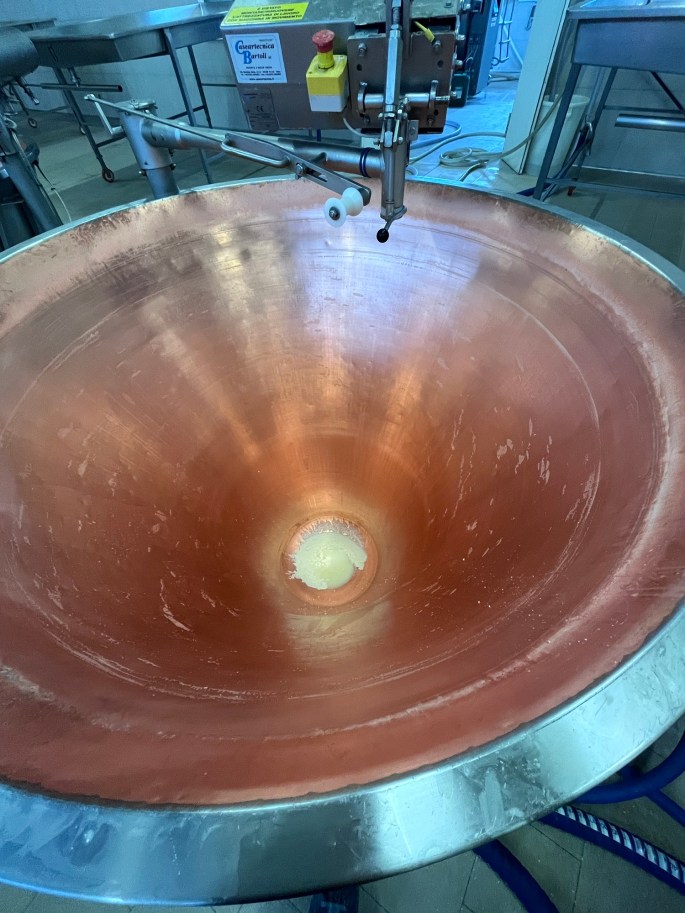

Milk product is placed into these heated copper bowls.

This is when we arrived. The solid matter comes together and at this point the gentleman was loosening that which was at the bottom of the pot.

The pictures below show more of the next few steps.

The cheese master was involved in the next steps, a culmination of 10 years work. If he makes a mistake, two rounds of cheese are lost.

A hydraulic lift assisted with putting these into the cheese molds.

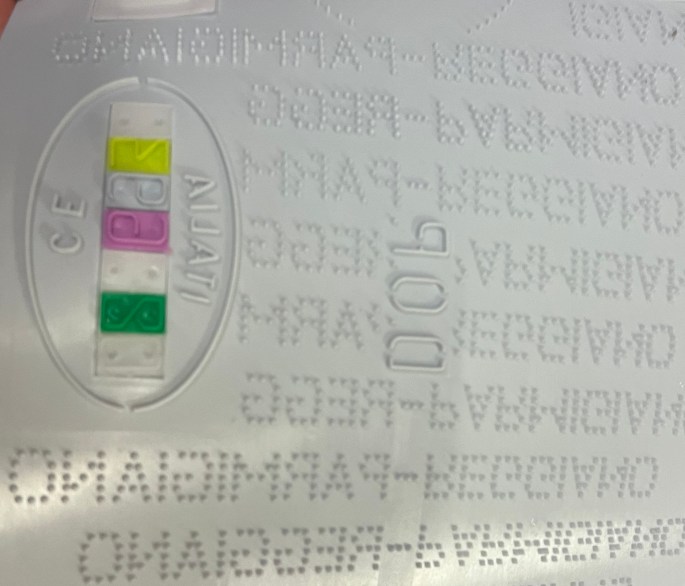

The cheese was stamped and strict records are kept to track this until sold to the consumer.

This mold ultimately indicates this is Parmesan cheese and other important info.

They are soaked in salted water before drying and then put into the warehouse next door.

And what a sight to see – amazing!

I don’t think I can fit one of these into my suitcase – but I’d like to try.

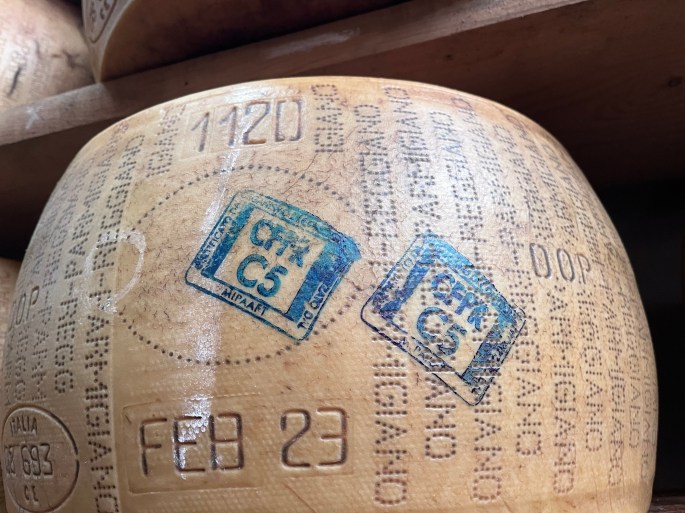

Inspections occur periodically and the wheels are stamped at that time.

So we asked how the mold impressions seem to darken during the process. The answer……..cheese dust. Huh? We got lucky and the machine that ‘brushes’ the cheese was at the very end of the row.

Split the video because the ‘brushing’ went on for quite a while. But then the cheese, goes back into its original space, turned upside down.

Another step is tapping the cheese round as part of the inspections.

Before leaving the drying warehouse, we captured one photo. There is a.l.o.t. of cheese here.

But you know………………..there is one step that needs to occur before all of this starts.

This rooster wanted to prove they ruled the area.

One cow wanted to be the center of my attention.

We walked past this contraption and what was happening? If you have an itch you can’t reach, come to the brush and it does the job (and keeps things clean and cows happy).

Remove the hairnets and the booties and it was time to taste their goodies. The front part of this building was a market where many locals stop in. I mentioned Labrusca in one of my earlier posts – love it. Finally, a red wine with a bit of ‘sparkle’ that was a dry wine. Who knew there were so many options. Not me!

All the products were either made here (cheese) or sold in their market. Perfect timing for a snack during the tour.

Those round ‘crackers’ seen below – parmesan cheese crisps – delicious!

I originally was going to have 1 post for the tour, but after I started writing, I’d rather break it down into manageable bites – more coming soon.